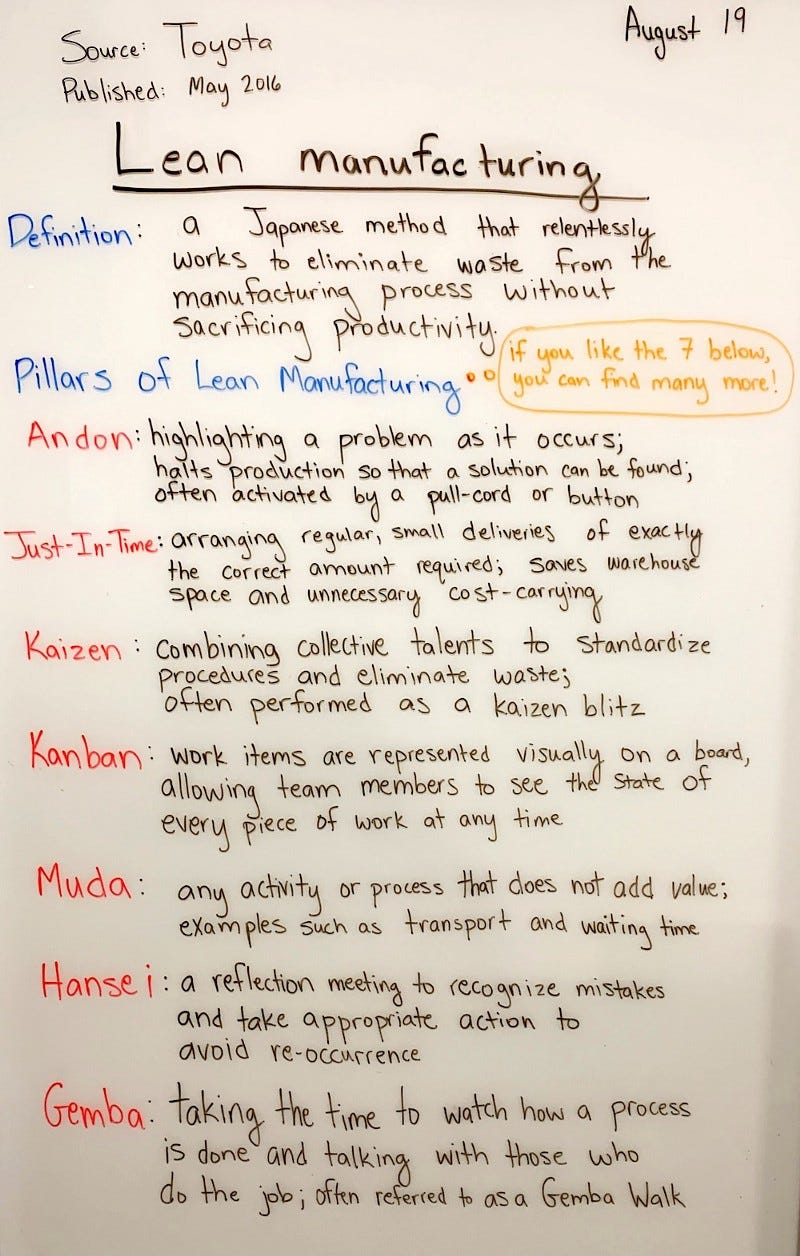

Lean Manufacturing

Source: Toyota

Published: May 2016

Lean Manufacturing

Circulated: August 19, 2019

Definition: a Japanese method that relentlessly works to eliminate waste from the manufacturing process without sacrificing productivity.

Pillars of lean manufacturing:

Andon: highlighting a problem as it occurs; halts production so that a solution can be found; often activated by a pull-cord or button.

Just-In-Time: arranging regular, small deliveries of exactly the correct amount required; saves warehouse space and unnecessary cost-carrying.

Kaizen: combining collective talents to standardize procedures and eliminate waste; often performed in a kaizen blitz.

Kanban: work items are represented visually on a board, allowing team members to see the state of every piece of work at any time.

Muda: any activity or process that does not add value; examples such as transport and waiting time.

Hansei: a reflection meeting to recognize mistakes and take appropriate action to avoid re-occurrence.

Gemba: taking the time to watch how a process is done and talking with those who do the job; often referred to as a Gemba Walk.